How our screen printing process works

Selecting Apparel for Custom Screen-Printing

There are many choices when it comes to selecting apparel that works for you. Screen-printed t-shirts are a popular option but so much more is available in our online catalogs. We offer basic t-shirts, elevated supersoft t-shirts, sweatshirts, hoodies, moisture wicking t-shirts, sweatpants, shorts, rally towels, tote bags and more. We're glad to help you pick out the best product for your project and have many samples on our showroom floor where you can feel the fabrics, see the color selection, and even try on apparel.

We have 3 online catalogs to explore, and additional options are available for specialized garments & accessories.

We have 3 online catalogs to explore, and additional options are available for specialized garments & accessories.

Concept to Approved DesignBegin with a concept of the art you have in mind. This can be as simple as a hand sketched drawing on paper, or a photo of a design that you like. If you already have your artwork in vector format (.eps preferred), please submit it to us via email.

Once we have an idea of your desired finished product, we take the concept into vector graphics software to create a finalized piece of art. You will receive a design proof with the final art, colors, and ink colors. It is best to view your artwork proof on a computer monitor or other large screen to make it easier to see the details and let us know if you would like revisions before your design goes to the press. |

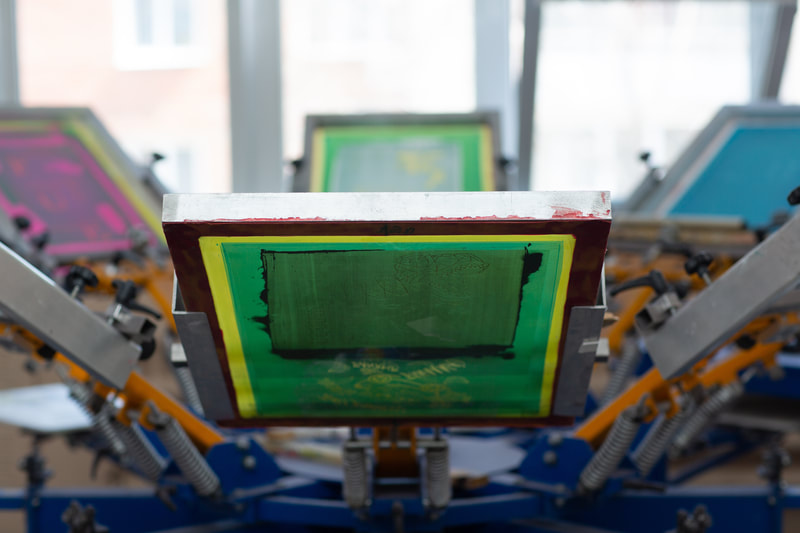

Silkscreening to the Apparel

Once your design concept is approved and all of your blank apparel is ordered, we use the vector artwork to create silkscreens for the project. This involves printing onto a transparent film which is used to create the screens (a film and a screen for each color in your design.) These screens are carefully aligned onto a screen printing press and ink is loaded for each color.

This setup process must be done precisely in order to produce a clean, sharp, professional looking print. Each apparel item is loaded on to the press and ink is applied (one color at a time) using a squeegee to press it through the fine mesh of the silkscreen. Once all of the colors have been applied, the apparel is removed from the press and cured in an oven to set the ink.

This setup process must be done precisely in order to produce a clean, sharp, professional looking print. Each apparel item is loaded on to the press and ink is applied (one color at a time) using a squeegee to press it through the fine mesh of the silkscreen. Once all of the colors have been applied, the apparel is removed from the press and cured in an oven to set the ink.

Final Steps & Notes

Once your items are complete they are neatly stacked and placed into a box, separated by size. We also offer folding and bagging services. The screens are then removed from the press, and thoroughly cleaned (removing all traces of your artwork), and re-used for another project. Our inks and screen cleaning supplies are non-toxic and environmentally safe.

While we do not have a minimum order, it is important to note that time spent setting up artwork and the press is the same whether ordering 3 shirts or 3000. To get more value for your setup, we recommend increasing your quantity to achieve a better per-piece price. Unless otherwise specified, our quotes include standard artwork and setup, so you get an all-inclusive per-piece price. (Excludes Indiana sales tax, if applicable.)

While we do not have a minimum order, it is important to note that time spent setting up artwork and the press is the same whether ordering 3 shirts or 3000. To get more value for your setup, we recommend increasing your quantity to achieve a better per-piece price. Unless otherwise specified, our quotes include standard artwork and setup, so you get an all-inclusive per-piece price. (Excludes Indiana sales tax, if applicable.)

Contact us today for a free quote on your custom screen-printed apparel